Izindaba Zemboni

-

Izinzuzo zokusebenza ze-Cast Copper Alloys

1. Izici zenqubo: Ama-alloy amaningi ethusi anokuncipha okukhulu, ukuthi ukulandelana kokuqinisa kufanele kulawulwe ngesikhathi sokuphonsa ukuze kumiswe ukwakheka kwemigodi yokuncipha.Ithusi eliwuthayela lifakwe i-oxidized kahle ngaphakathi kwesimo soketshezi, ukuze ukugeleza kungaphazamisi ngesikhathi sokuthela....Funda kabanzi -

Ukusetshenziswa kwe-beryllium copper alloy kusikhunta sezimoto

Isiphetho sokusetshenziswa kwe-beryllium copper alloy ku-automobile die Ukusebenza kokugxiviza kwephaneli yezimoto kungenye yezinqubo ezine ezinkulu zokukhiqiza izimoto, futhi iyisixhumanisi esiyinhloko ekukhiqizeni umzimba.Izinga lekhwalithi yezingxenye zokunyathela lenza isisekelo se-q...Funda kabanzi -

Yiziphi izindlela zokukhetha izinto zokwakha ama-alloys ethusi?

I-Brass inomsebenzi omuhle wokucubungula futhi ivame ukusetshenziselwa ukusika izesekeli ezihlukahlukene.Phakathi kwazo, izinto zethusi ezisetshenziswa kakhulu ekusikeni ithusi eliqukethe i-Pb.Ithusi eliqukethe umthofu linamakhemikhali amahle kakhulu, umzimba, imishini kanye nezindawo zokusika mahhala, futhi iyiphoyisa elisetshenziswa kakhulu...Funda kabanzi -

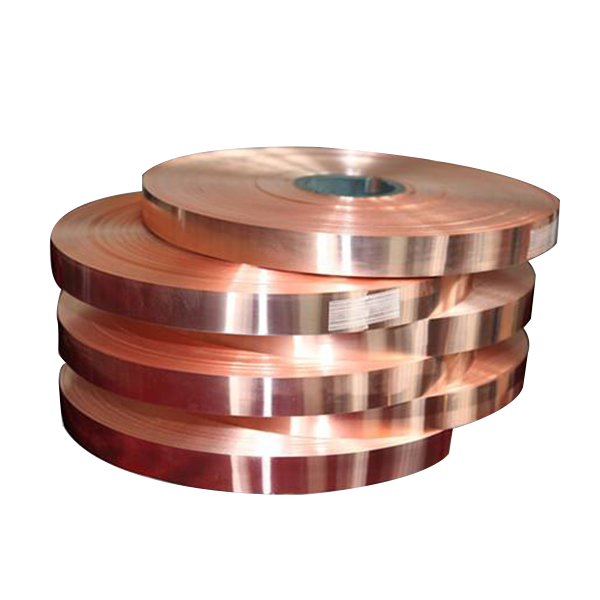

Ukukhethwa Kwenqubo Yokuhlanganisa Kweshidi Lethusi Lethayela

1. Izinga lokushisa elishisisayo, isikhathi sokubamba kanye nendlela yokupholisa: Izinga lokushisa lokushintsha kwesigaba sepuleti lethusi likathayela lisuka ku-α→α+ε licishe libe ngu-320 ℃, okungukuthi, izinga lokushisa lokushisa lingaphezu kuka-320 ℃, futhi ukwakheka kwalo kuyi-single- Isakhiwo sesigaba, size sishisiswe sibe ngu-930 Isakhiwo sesigaba se-liquid a...Funda kabanzi -

Ukushisela phakathi kwepuleti lethusi le-tin nensimbi

Ipuleti lethusi likathayela limelana kakhulu nokugqwala emkhathini, emanzini olwandle, emanzini ahlanzekile nesitimu, futhi lisetshenziswa kakhulu kumabhayela esitimu kanye nezingxenye zemikhumbi yasolwandle.Uhla lokuqiniswa kwepuleti lethusi le-tin likhulu, futhi ukuhlukaniswa kwe-dendrite kubi kakhulu;akulula ukwakha i-concentrated s...Funda kabanzi -

Ukusetshenziswa okubanzi kwethusi le-aluminium empilweni

Ithusi le-aluminium ngeke likhiqize izinhlansi ngaphansi kokuthinteka, futhi kungase kujwayele ukwenza izinto zamathuluzi ezingashisi.kungcono kakhulu conductivity ezishisayo kanye ukuqina ezinzile.yizinzuzo zokuklwebha i-workpiece njalonjalo, futhi isiphenduke uhlobo olungena esikhundleni sesikhunta.yi p...Funda kabanzi -

Ububanzi bokusebenza kwepuleti lethusi le-tungsten

Ipuleti yethusi ye-Tungsten ihlanganisa izinzuzo ze-tungsten yensimbi nethusi.Phakathi kwazo, i-tungsten inephuzu elincibilikayo eliphakeme kanye nokuminyana okuphezulu.Iphuzu lokuncibilika kwe-tungsten lingu-3410 degrees Celsius, kanti indawo yokuncibilika yethusi ingu-1083 degrees Celsius.I-Copper inogesi omuhle kakhulu kanye ne-thermal c ...Funda kabanzi -

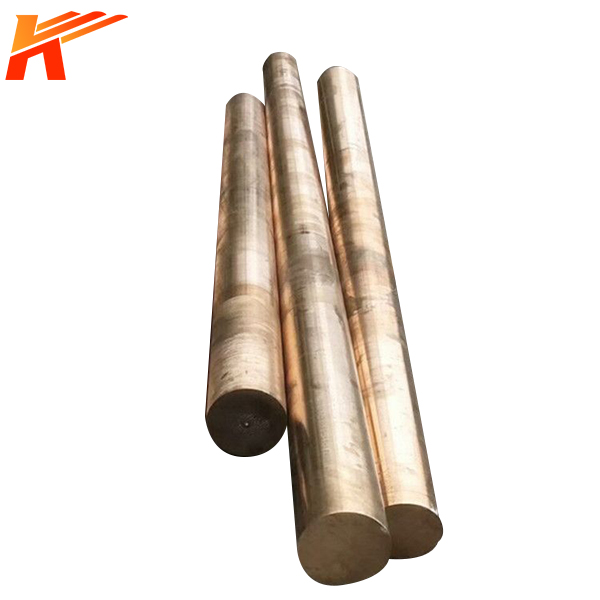

Isimiso senqubo yokwenza induku yethusi

1. Zonke izakhi zinciphisa ukuqhutshwa kukagesi kanye ne-thermal conductivity yenduku yethusi ngaphandle kokukhetha.Zonke izakhi ziyancibilika endukwini yethusi, okubangela ukuhlanekezela kwe-lattice yenduku yethusi, okubangela ukuhlakazeka kwamagagasi lapho ama-electron amahhala egeleza eqonde ngqo, okwenza i-resistivi...Funda kabanzi -

Izinyathelo zokuqapha enqubweni ye-extrusion yezinduku zethusi

Ngesikhathi senqubo ye-extrusion yenduku yethusi, ingot ingaphansi kokucindezeleka kokucindezela kwezindlela ezintathu ku-cylinder extrusion futhi ingakwazi ukumelana nenani elikhulu lokuguqulwa;lapho i-extruding, kufanele isekelwe ezicini ze-alloy, imininingwane kanye nezidingo zobuchwepheshe ze...Funda kabanzi -

Izici kanye nokusetshenziswa kwe-Chromium Zirconium Copper

I-Chromium zirconium copper (CuCrZr) ukwakheka kwamakhemikhali (ingxenyana yobuningi) % (Cr: 0.1-0.8, Zr: 0.3-0.6) ubulukhuni (HRB78-83) conductivity 43ms/m lokushisa okuthambisayo 550 ℃ I-Chromium zirconium yethusi, ukuqina kwethusi kagesi conductivity kanye conductivity ezishisayo, ukugqoka ukumelana...Funda kabanzi -

Umthelela we-Cerium Ezimpahleni Ze-Tin Phosphor Bronze Alloy

Ukuhlola kufakazele umthelela we-cerium kusakhiwo se-microstructure ye-tin-phosphor bronze QSn7-0.2 alloy ephonswe, yenziwa i-homogenized futhi yaphinde yahlanganiswa.I-mesh iba yinhle, futhi ukwakheka okusanhlamvu ngokusobala kucwengisiswa ngemuva kokukhishwa kwe-deformation.Yengeza inani elincane lomhlaba ongavamile...Funda kabanzi -

Iyini ukuminyana kwethusi le-tin?

Amandla adonsela phansi ethusi we-tin ρ (8.82).Ithusi lingahlukaniswa izigaba ezimbili: ithusi lethayela kanye nethusi elikhethekile (okungukuthi i-Wuxi bronze).Ngemikhiqizo yokusakaza, engeza igama elithi “Z” ngaphambi kwekhodi, njengokuthi: I-Qal7 isho ukuthi okuqukethwe kwe-aluminium kungu-5%, okunye kuyithusi.Ukulingisa ithusi...Funda kabanzi